威胜信息获评国家卓越级智能工厂Willfar Earns Nat’l Excellent Smart Factory

12月3日,2025年湖南省智能制造推进大会在长沙举行。本次大会由湖南省工业和信息化厅主办,中国信息通信研究院、湖南省工业和信息化行业事务中心、长沙经济技术开发区管委会、湖南省智能制造协会承办,汇聚行业精英共商智能制造发展大计。国家智能制造专家委员会主任、华中科技大学教授李培根,工业和信息化部装备工业一司有关负责人,省工业和信息化厅党组成员、副厅长刘卫东,省工业和信息化行业事务中心党委书记、主任邓光亮等出席。全省工业和信息化主管部门负责人,全省领航级、卓越级、先进级智能工厂和优秀智能制造系统解决方案供应商代表300余人参加。威胜信息被授予“国家卓越级智能工厂”,威胜信息总裁李先怀出席会议并上台领奖。

聚焦数智转型,湖南智能制造再启新程

活动现场,李培根以“深化企业数智化转型升级”为题作主旨报告,系统剖析数智化转型的核心逻辑与实践路径,为湖南智能制造提供专业指引。中国信息通信研究院首席专家续合元对智能工厂梯度培育相关政策进行深度解读,助力企业精准把握政策导向。

刘卫东在总结讲话中表示,面向“十五五”,湖南将牢牢把握制造业智能化、绿色化、融合化发展趋势,从夯实智能制造基础支撑能力、系统推进智能工厂梯度培育、推动智能制造全面均衡发展、完善优化智能制造生态体系四个方面发力,加快构建覆盖中试熟化、标准引领、生态协同的智能制造服务体系,率先探索下一代智能制造“湖南范式”,力争打造智能制造“湖南新样板”,为持续用力打造国家重要先进制造业高地提供坚实支撑。

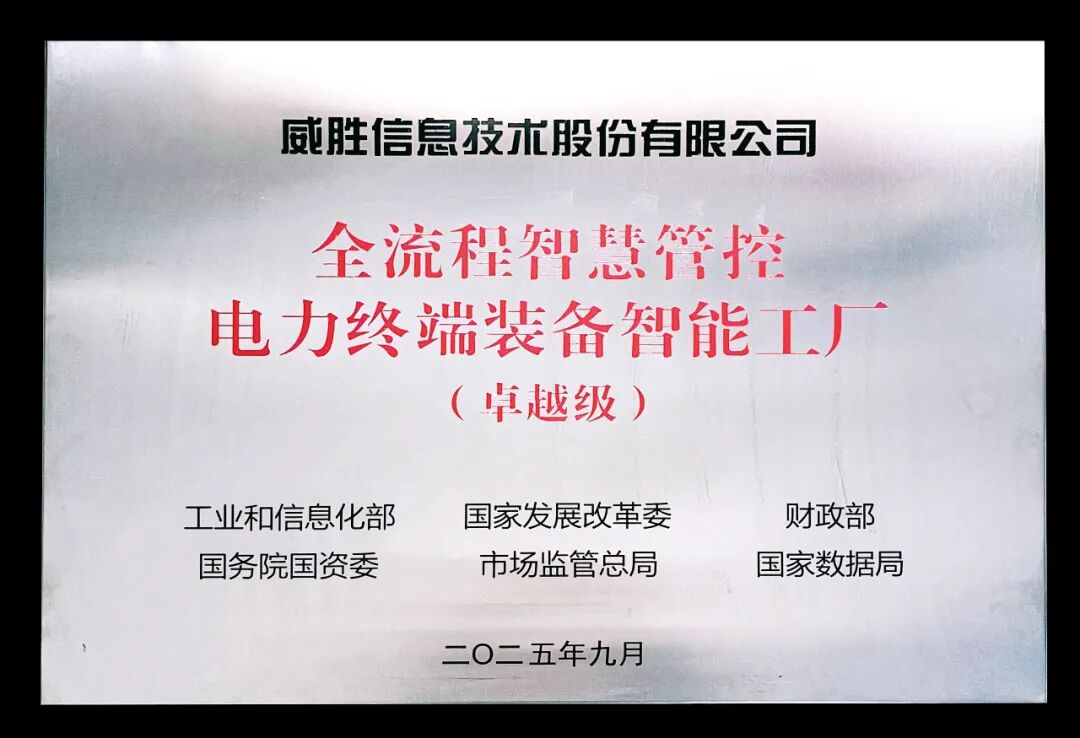

大会现场还举行了授牌仪式,威胜信息再添一项国家级重磅荣誉,被授予“2024-2025国家卓越级智能工厂”,不仅标志着威胜信息的数字化制造能力达到行业领先水平,也为整个能源物联网装备领域的智能化转型树立了崭新标杆。

从“制造”到“智造”,威胜信息凭三大核心优势脱颖而出

区别于传统工厂的自动化改造路径,威胜信息以“AI+先进制造深度融合”为核心理念,围绕“数字威胜”五年关键战略行动计划,充分运用5G、工业互联网、大数据、人工智能与云计算等新一代信息技术,构建起覆盖“智能设计、智能工艺、智能物流、智能计划、智能生产、数字质量”的智能制造核心体系,最终打造出“装备控制+制造执行+经营管理+经营决策”四位一体的智能制造新模式。

通过工厂的数字化规划与建设,实现从设备、产线到车间、工厂的系统建模与优化。以数字孪生技术为支撑,构建车间或工厂级虚拟模型,结合5G和工业互联网技术,与真实工厂进行数据交互,辅助生产状态监控和运营决策。企业部署智能制造装备、国产化工业软件和信息系统,建设5G专网、数据中心及AI算力设施,加强网络安全和数据管控,为预测性维护和智能物流提供技术支持。通过“规划设计-建设实施-运营优化”的协同,缩短建设周期,降低运维成本,推动智能制造向高效协同方向发展。此外,公司还参与制定多项国家/行业标准,为行业提供“技术-标准-实践”三位一体的转型方案,示范效应持续凸显!

此次湖南省智能制造推进大会的召开,不仅为省内企业搭建了交流合作的平台,更明确了湖南智能制造的发展方向。面向未来,威胜信息将锚定“双碳”目标持续发力,以智能制造为核心驱动力,开启高质量发展新征程。

On December3rd,the2025Hunan Provincial Intelligent Manufacturing Promotion Conference was held in Changsha.Hosted by the Hunan Provincial Department of Industry and Information Technology and co-organized by the China Academy of Information and Communications Technology,Hunan Provincial Industry and Information Technology Industry Affairs Center,Administrative Committee of Changsha Economic and Technological Development Zone,and Hunan Intelligent Manufacturing Association,the conference gathered industry elites to discuss the development of intelligent manufacturing.Li Peigen,Director of the National Intelligent Manufacturing Expert Committee and Professor of Huazhong University of Science and Technology,relevant responsible persons from the First Department of Equipment Industry of the Ministry of Industry and Information Technology,Liu Weidong,Member of the Party Leadership Group and Deputy Director of the Hunan Provincial Department of Industry and Information Technology,and Deng Guangliang,Secretary of the Party Committee and Director of the Hunan Provincial Industry and Information Technology Industry Affairs Center,attended the event.More than300participants included responsible persons from industrial and information technology authorities across the province,as well as representatives of leading-level,excellent-class,advanced-level smart factories and outstanding intelligent manufacturing system solution providers in Hunan.Willfar was awarded the"National Excellent-Class Smart Factory",and Li Xianhuai,President of Willfar,attended the conference and accepted the award on stage.Focus on Digital-Intelligent Transformation:Hunan Intelligent Manufacturing Embarks on a New Journey At the event,Li Peigen delivered a keynote report titled"Deepening Enterprises'Digital-Intelligent Transformation and Upgrading",systematically analyzing the core logic and practical paths of digital-intelligent transformation and providing professional guidance for Hunan's intelligent manufacturing.Xu Heyuan,Chief Expert of the China Academy of Information and Communications Technology,conducted an in-depth interpretation of policies related to the gradient cultivation of smart factories,helping enterprises accurately grasp policy orientations.

In his concluding speech,Liu Weidong stated that facing the"15th Five-Year Plan"period,Hunan will firmly grasp the development trends of intelligence,greenization,and integration in the manufacturing industry.It will focus on four key areas:consolidating the basic supporting capacity of intelligent manufacturing,systematically advancing the gradient cultivation of smart factories,promoting the comprehensive and balanced development of intelligent manufacturing,and improving and optimizing the intelligent manufacturing ecosystem.Efforts will be made to accelerate the construction of an intelligent manufacturing service system covering pilot-scale maturation,standard leadership,and ecological collaboration,take the lead in exploring the"Hunan Model"of next-generation intelligent manufacturing,and strive to create a"new Hunan benchmark"for intelligent manufacturing,providing solid support for building a national important advanced manufacturing highland.

An award ceremony was also held at the conference.Willfar added another heavyweight national honor,being awarded the"2024-2025National Excellent-Class Smart Factory".This not only marks that Willfar's digital manufacturing capacity has reached the industry-leading level but also sets a new benchmark for the intelligent transformation of the entire energy IoT equipment sector.From"Manufacturing"to"Intelligent Manufacturing":Willfar Stands Out with Three Core Advantages Different from the automation transformation path of traditional factories,Willfar takes"in-depth integration of AI+advanced manufacturing"as its core philosophy.Centering on the five-year key strategic action plan of"Digital Willfar",it fully applies new-generation information technologies such as5G,industrial internet,big data,artificial intelligence,and cloud computing to build a core intelligent manufacturing system covering"intelligent design,intelligent process,intelligent logistics,intelligent planning,intelligent production,and digital quality".Ultimately,it has created a four-in-one new intelligent manufacturing model of"equipment control+manufacturing execution+operation management+business decision-making".

Through the digital planning and construction of the factory,systematic modeling and optimization from equipment and production lines to workshops and the entire factory have been realized.Supported by digital twin technology,workshop or factory-level virtual models are built,which interact with real factories through5G and industrial internet technologies to assist in production status monitoring and operational decision-making.The enterprise has deployed intelligent manufacturing equipment,domestic industrial software and information systems,built5G private networks,data centers,and AI computing power facilities,and strengthened network security and data management and control,providing technical support for predictive maintenance and intelligent logistics.Through the collaboration of"planning and design-construction and implementation-operation optimization",the construction cycle is shortened,operation and maintenance costs are reduced,and intelligent manufacturing is promoted towards efficient collaboration.In addition,the company has participated in formulating a number of national/industry standards,providing the industry with a"technology-standard-practice"trinity transformation plan,and its demonstration effect continues to stand out!

The holding of the Hunan Provincial Intelligent Manufacturing Promotion Conference has not only built a platform for exchange and cooperation among enterprises in the province but also clarified the development direction of Hunan's intelligent manufacturing.Looking forward to the future,Willfar will continue to focus on the"dual carbon"goals,take intelligent manufacturing as the core driving force,and embark on a new journey of high-quality development.

0人